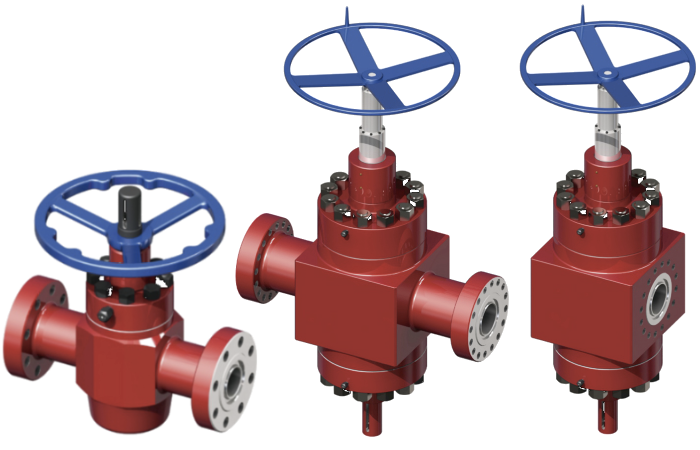

Slab Gate Valve

With temperature rating for API Spec 6A in L, P, R, S, T, and U type,

available for temperatures up to 350° C or 650° C.

Pressure classes 2000psi, 3000psi, 5000psi, 10000psi,

15000psi, 20000psi. Material level API 6A AA~HH, product

specification level PSL1~3G, performance level PR1~2.

Features:

- Simple structure, easily removable gate and seat assembly.

- Bi-directional use, long service life.

- Thrust bearing for minimum torque.

- Packing injection fitting for seal integrity.

- Gate and seat with hard facing for maximum wear and corrosion resistance.

- Forged body construction.

- Can be fitted with expanding or slab gates.

- Available as manual or actuated versions.

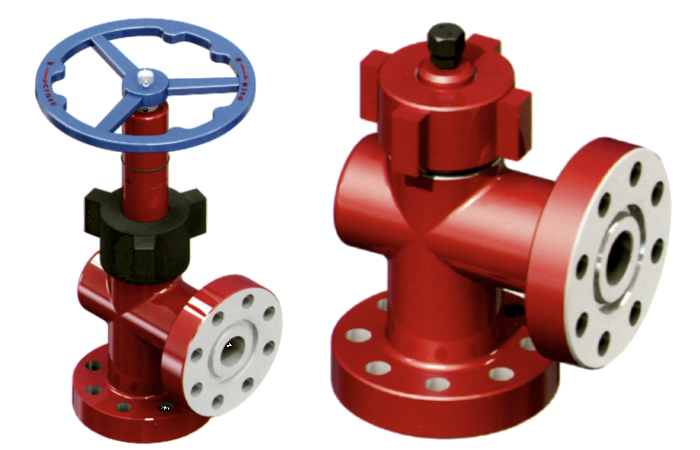

Choke Valve

The choke valve, a main component of the Christmas tree, is designed to control

production rate of the oil well, with working pressure up to 20,000psi.

Choke valves can be classified as follows: adjustable choke valves and positive

choke valves. By rotating handwheel the adjustable choke valve is designed to

adjust the effective area available for the flow to accomplish control of

production rate. The positive choke valve is design to accomplish control of

production rate by changing flow beans.

The quick coupling nut used for connecting the bonnet and body allows fast make-up

and break-out.

Stem tip and bean are fabricated from special carbide alloys for

corrosion and abrasion resistance.

Indicator with scale marks allows exact positioning, thus actual orifice area.

Technical Data:

- Working Pressure: 2,000 psi - 20,000 psi

- Nominal Bore diameter: 1-13/16" ~ 13-5/8"

- Temperature Class: K~V

- Product Specification Level: 1~4

- Performance Requirement: PR1~2

- Material Class: AA~HH

- Working Medium: Crude oil, natural gas, drilling fluid

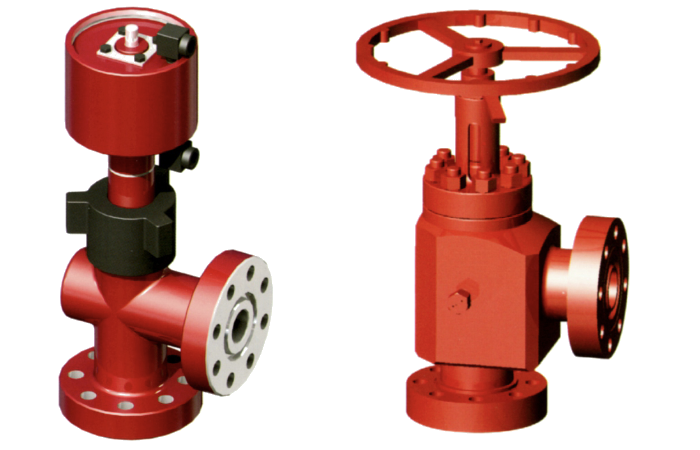

Orifice Plate Choke Valve

Orifice plate choke valve is used for manifold equipments, such as drilling, fracturing, mud circulating, ground high-pressure gas injecting and producing, etc.

The most remarkable feature of the valve is that pressure difference between inlet and outlet can press the two orifice together closely to realize the function of sealing and cutting off when it is closed. Especially in emergencies such as sudden rise or sudden drop of the pressure because of leakage, it closes and cuts off automatically through pre-set pressure signal value of high and low pressure sensor. Thus, accidents can be avoided.

It’s main advantage is the long working life and elevated erosion/corrosion resistance in comparing with other choke valves.

The choke plates are made from two pieces of solid special carbon tungsten.

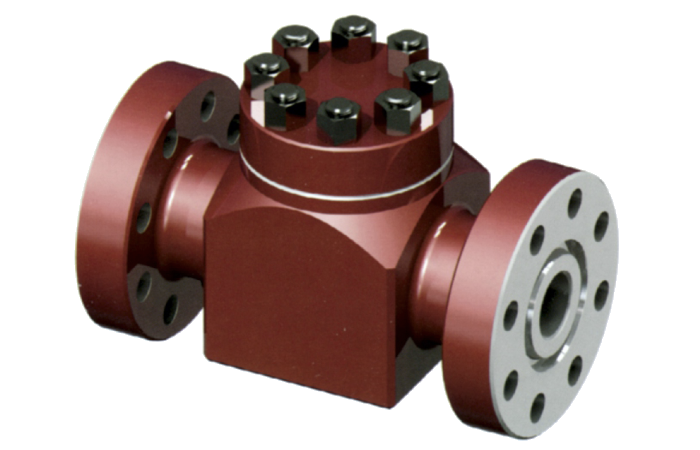

Check Valve

Check valves are used primarily in high pressure mud choke manifolds and high pressure Christmas tree injection and kill lines. End connections can be flanged, clamp hub, butt weld, or a combination. These valves can be supplied to all API 6A temperature and retained fluid classifications.

Check valve seal between valve disk and body by fluid pressure - the higher the fluid pressure, the tighter the seal.

The body is made of forged alloy steel with excellent mechanical and corrosion properties. Bonnet is bolted type.

Carbide sealing surfaces have excellent anti-abrasion and corrosion resistance. The valves are suitable for H2S service.

Technical Data:

- Working Pressure: 2,000 psi - 15,000 psi

- Nominal Bore diameter: 1-13/16" ~ 13-5/8"

- Temperature Class: K~V

- Product Specification Level: 1~4

- Performance Requirement: 1~2

- Material Class: AA~HH

- Working Medium: Petroleum, natural gas

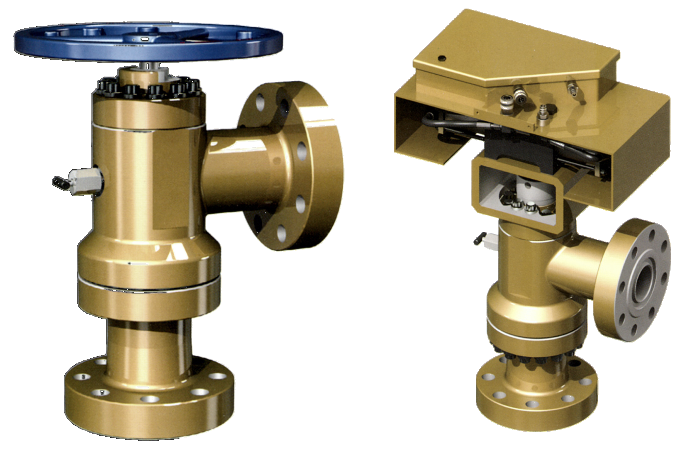

Plug Valve

Plug valve is a necessary part that is applied to high pressure manifold in well cementing and fracture service, also suitable for high pressure fluid control system.

It is compact, has easy maintenance, low torque, and rapid operation, which makes it an ideal valve for cementing and fracturing manifolds.

Technical Data:

- Working Pressure: 2,000 psi - 15,000 psi

- Nominal Bore diameter: 1-13/16" ~ 13-5/8"

- Temperature Class: K~V

- Product Specification Level: 1~4

- Performance Requirement: 1~2

- Material Class: AA~HH

- Working Medium: Petroleum, natural gas

For more information on our products, or to request pricing and availabilty, please click the Contact Valpro.